-40%

220V End Mill Re-sharpening Machine CNC Endmill Sharpener Grinder φ2 - φ12mm y

$ 577.59

- Description

- Size Guide

Description

220V End Mill Re-sharpening Machine CNC Endmill Sharpener Grinder φ2 - φ12mmFast Shipping DHL OR EMS

(The machine only support 220V)

New

Specification:

Model: ERM-12

Applicable diameters: φ2 ~ φ12mm

Applicable flutes: 2 flutes, 3 flutes, 4 flutes

Axial angles: Secondary clearance angle 6°, Primary bevel angle 20°, End gash angle 30°

Grinding wheel: SDC#220 (CBN for optional)

Power supply: 220V ± 10% AC

Motor output: 300W

Rated speed: 6000rpm

Dimensions: 290 * 260 * 230(mm)

Weight: 7.5KG

Standard accessories:

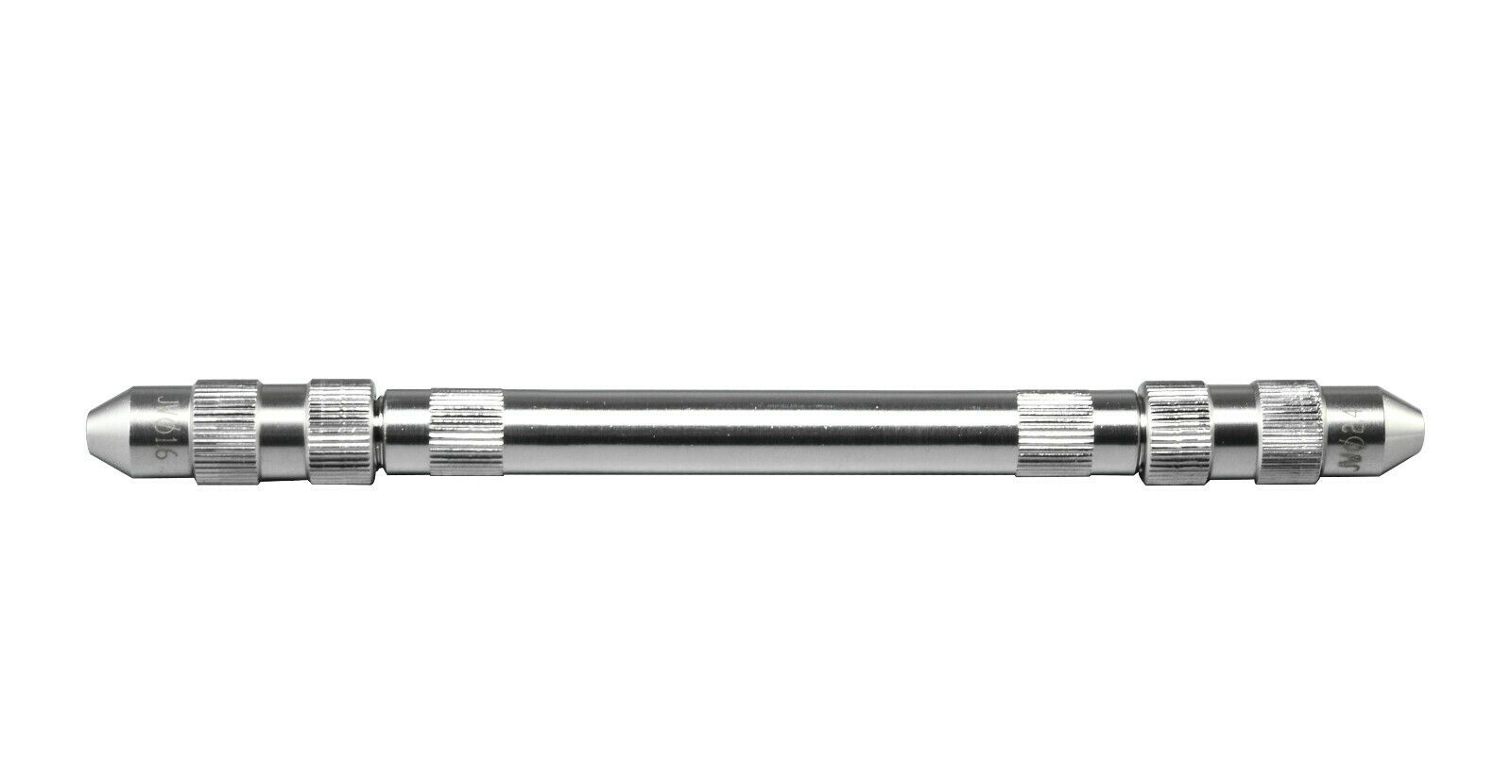

Collet * 7pcs, 2 flutes holder * 8pcs, 3 flutes holder * 8pcs, 4 flutes holder * 8pcs,

Case, Hexagon wrench, Brush, Power cord

Feature:

Help achieving sharpening of 2 flutes, 3 flutes and 4 flutes Φ2~Φ12 mill, without changing grinding wheel. Turn old mill to be a new one within just one minute.

The sharpening effciency improves 5 to 10 times

You only need to put the mill in holding assembly, adjust the length and direction of tool edge, and then put the fixed mill holding assembily to sharpening mouth and finish the sharpening for mill by rotaing and moving slightly.

Different special holding assembly for different diameter and different number of flutes mills, after sharpening, the mill edge width and notched width and angle of tool edge will be as well as that of the new one.

Easy to operate, you only need to fix teh holding assembly of tthe mill and totate and move it sligtly after ptu it in sharpening mouth; the sharpening for mill can be finished in 1 minutes which solve the problems of traditional sharpening such as complicate operating procedures and long sharpening time.

Save cost, you do not need to worry about high tool consumption and more and one old mill can be sharpened for decades of times.