-40%

370W Circular Saw Blade 80-700mm Grinder Sharpener Machine Chainsaw Slideable

$ 263.89

- Description

- Size Guide

Description

370W Circular Saw Blade 80-700mm Grinder Sharpener Machine Chainsaw SlideableIntroduction:

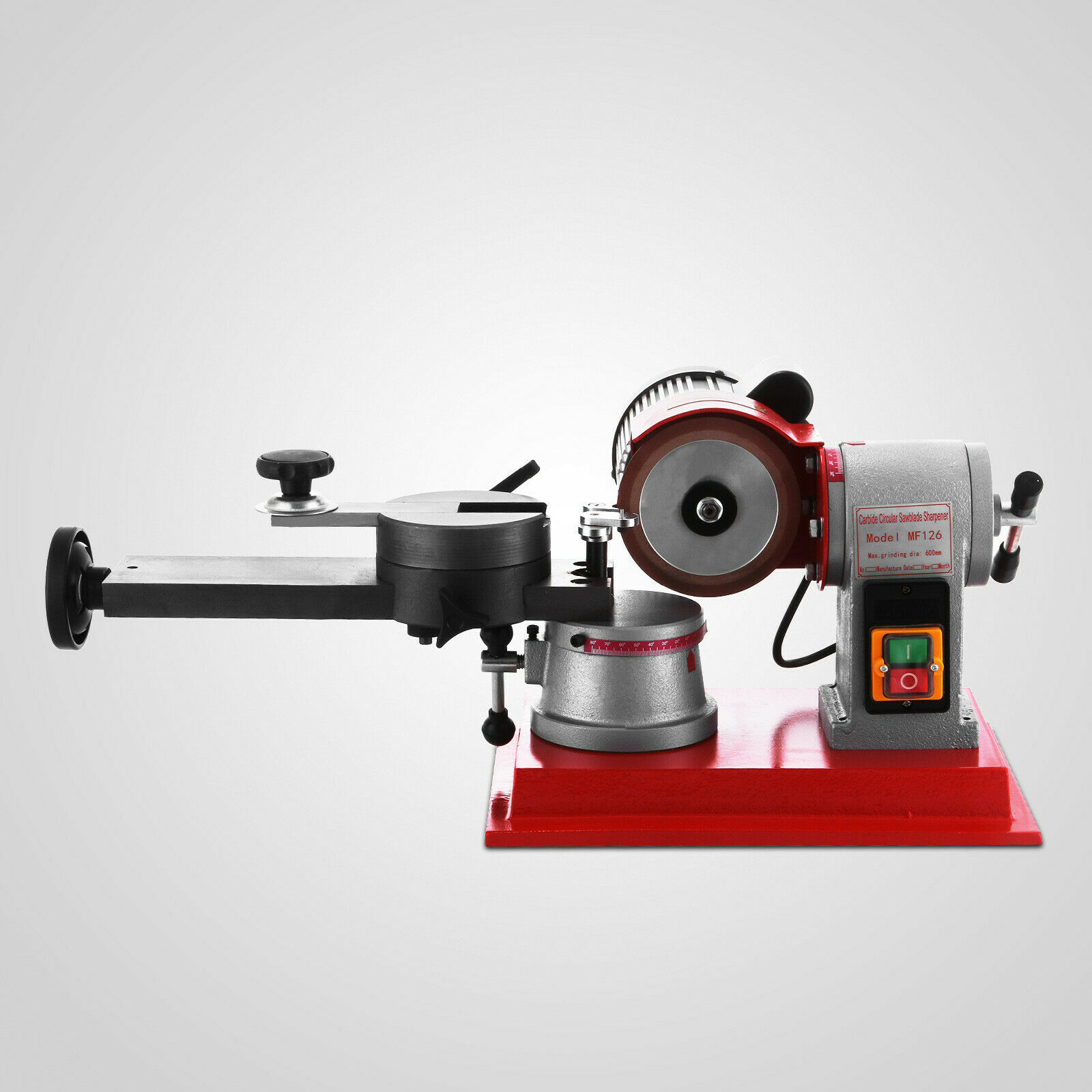

The machine is designed for sharpening various kinds of carbide tipped saw blades from size 80mm to 700mm. It's also suitable to grinde other material, such as plastic, wood, aluminum alloy for different purpose like furniture manufacturing, decoration etc. Its fascia can support the teeth of saw blades and other parts in order to prevent jumping and improve grinding quality. This item can shapen all the round saw blade, such as Skil saw. It adopts multi angle of swing, three dimensional slide structures to be in adaptation to the grinding of hard alloy saw blades with many specifications and purposes, which enables the grinding mill to maintain high accuracy and easy operation on any condition.

Circular carbide saw blade are widely used for cutting aluminum, wood and plastic materials. MF-126 type grinding machine is used for sharpening many sizes and types circular carbide saw blade. If you change the sanding wheel it can also sharp other common saw blade. It is a necessary assistant machine for cutting aluminum, wood and plastic materials.

Method of operation:

First, loosing the fascia, then adjust the angle of grinding blade and fasten.

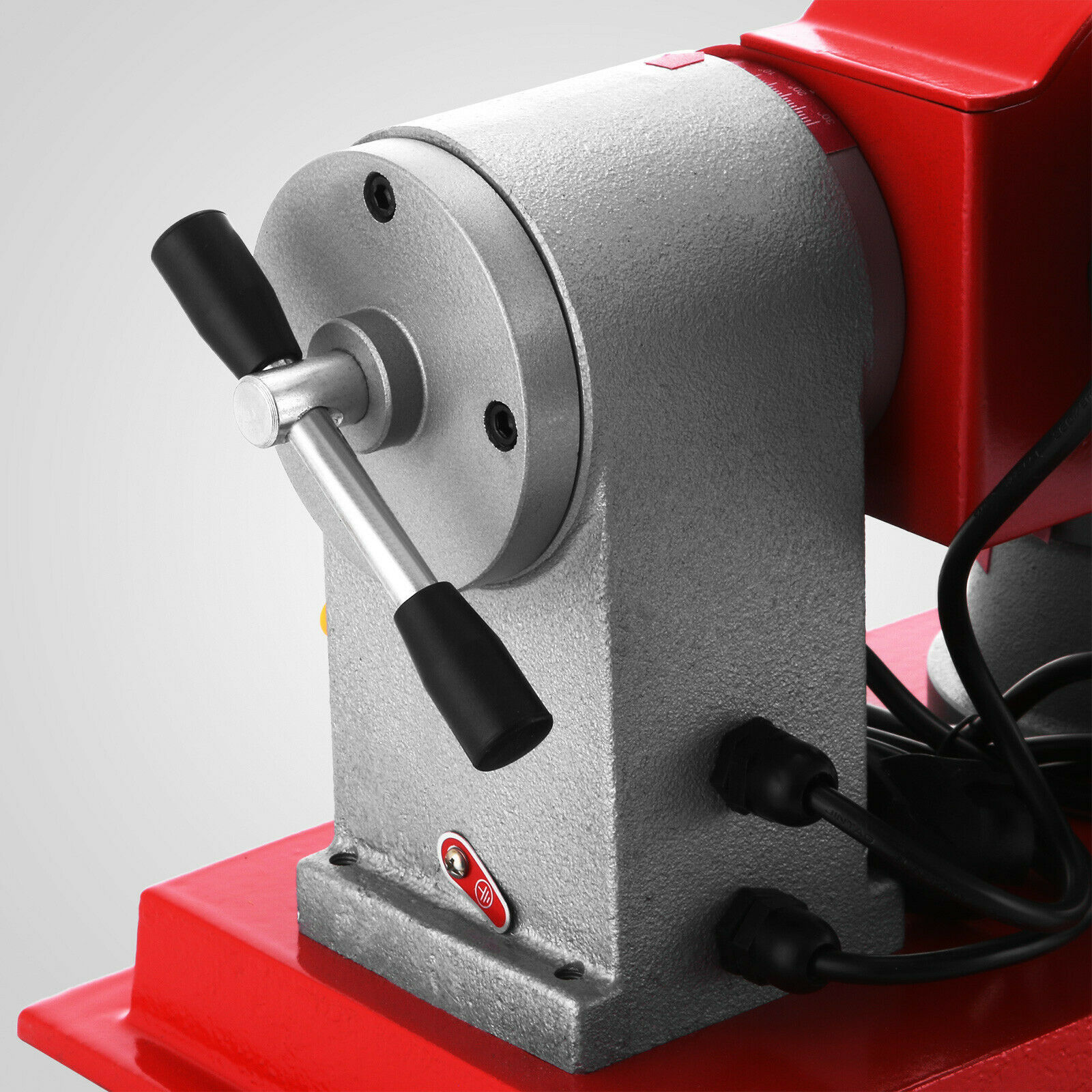

Second, adjusting of center axle.

Rotating the center axle to the grinding blade.

Pushing the center axle to the right.

Installing the saw blade ,rotate the wheel and decide the position of grinding surface saw teeth.

Rotating the rotation table to ensure the angle of grinding blade.

The cross angle between the grinding surface and work surface is about 5.

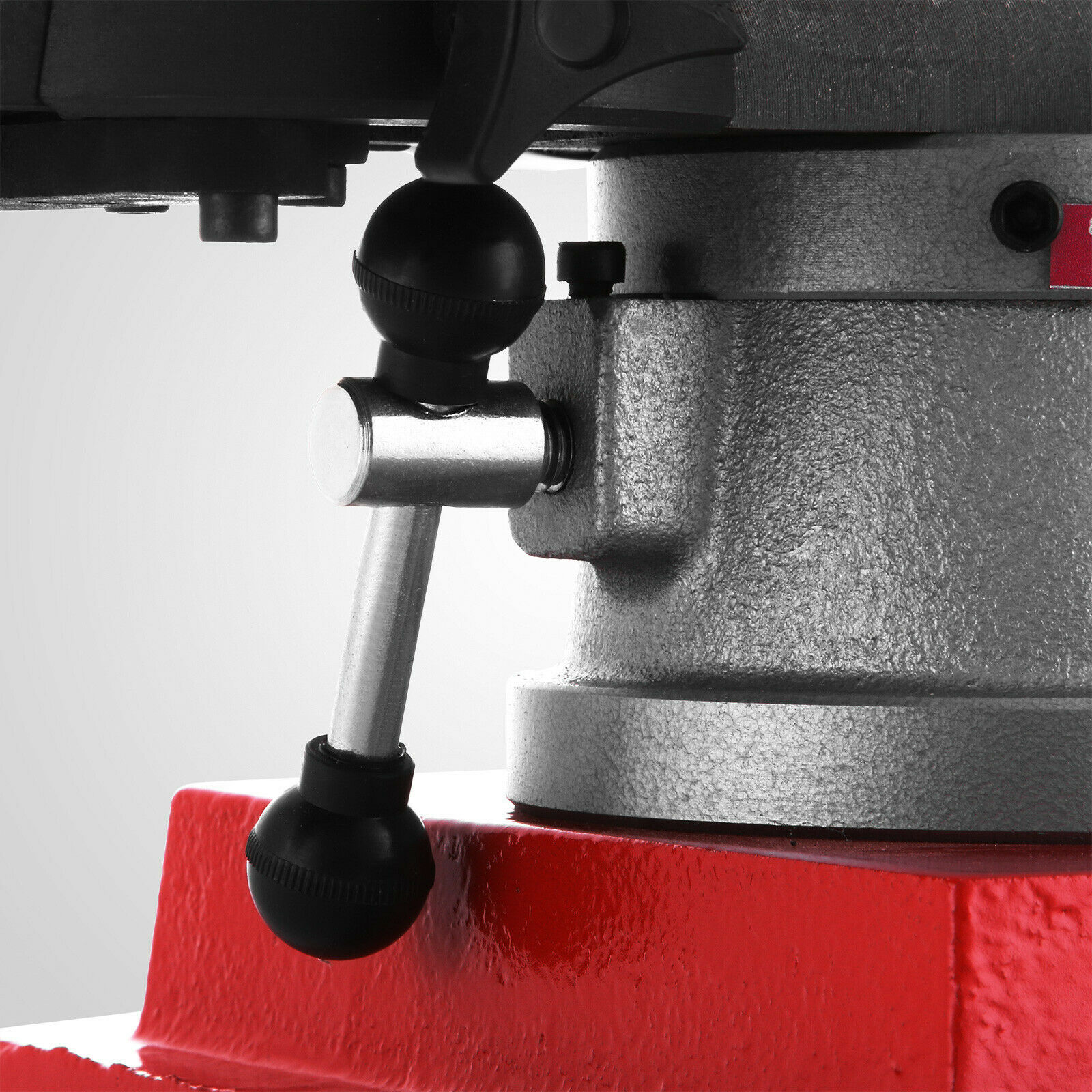

Third, adjusting of positioning assembly.

Adjusting the saw blade to the best grinding position, rotating the positioning frame and fascia.

Adjusting positioning pin to the proper base of saw teeth and leave gap of grinding quantity, fasten the fixed screw.

Fourth, adjusting the center axle to the same gap of grinding quantity to the right.

Last, when all the parts are fastened, the saw blade supported with hand will be grinded.

Safety remarks:

Should match the standard voltage; We must strictly take a good ground, install leakage circuit breakers.

The machine should be set in a dry, clean, steady and parallel place.

Release the round plat and then adjust the saw blade angle.

Check all parts that need locks before operation.

After the machine runs well then you can start the work.

Take off the electricity after work finishing.

Inform the factory before you change the machines.

1.base

2.box body

3.end cover

4.rotatary base

5.rotary table base

6.rotary table

7.slide base

8.slide disc

9.table

10.guide nut base

11.guide screw

12.slide block

13.frame

14.board

15.positioning board

16.safe cover

17.press board

18.adjusting bolt

19.upright post

20.long bolt

21.short bolt

22.long handle

23.short handle

24.positioning pin

25.mat cover

26.diamond wheel

27.cover

28.motor

29.rear stuck disc

30.fore stuck disc

31.big pin

32.small pin

33.hand wheel

34.round handle

35.turret handle

36.earth foot

37.adjusting bolt base

38.fastening handle

39.switch

40.screw

41.lirnit pin

42.washe

43.cover

Feature

The machine structure is strong and it can work on max diameter φ700mm.

The specially equipped motor has a very good running speed which can have a very good co-operation with the diamond sanding wheel.

The direction of the sharpening should be paralleled with the diamond sanding wheel, it is better for grinding the back teeth face.

This machine is designed for sharpening various kinds of carbide tipped saw blades from size 80mm to 700mm.

Also suitable to grind other material such as plastic, wood, aluminum alloy for different purpose like furniture manufacturing, decoration etc.

Steel chassis construction.

Grinding wheel angle control with large aluminum knob.

Will hold each blade head position by a position lock.

Extra 2 blade hole adapter.

X axis feed wheel, stable and very sharp grinding.

Rotary angle mark.

Specifications

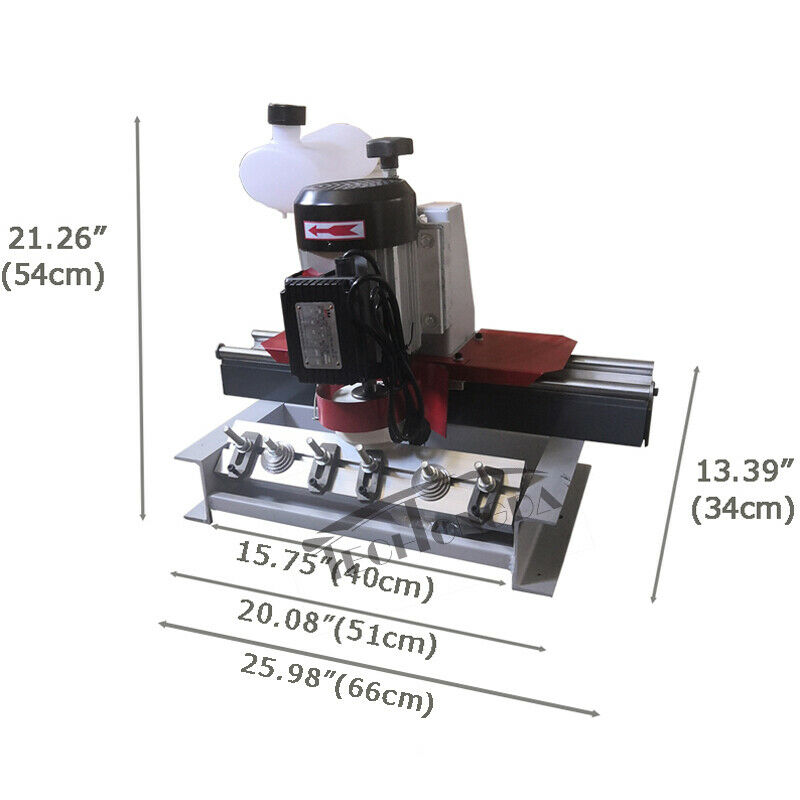

Power: 370 W

Voltage: 220V

Running Speed: 3400 RPM

Adjusting Angle Of The Wheel: ±20°

Handle Turning Angle: 30 Degrees From Left And 45 Degrees From Right

Working Diameter: 80 - 700 mm

Grinding Wheel Size: 4.92" / 125 mm

Bore Size Of Grinding Wheel: 1.26" / 32 mm

Sanding Wheel Dimensions: 4.92"

x

0.39"

x

1.26"

x

0.2"

x

0.08" / 125

x

10

x

32 x 5 x 2 mm

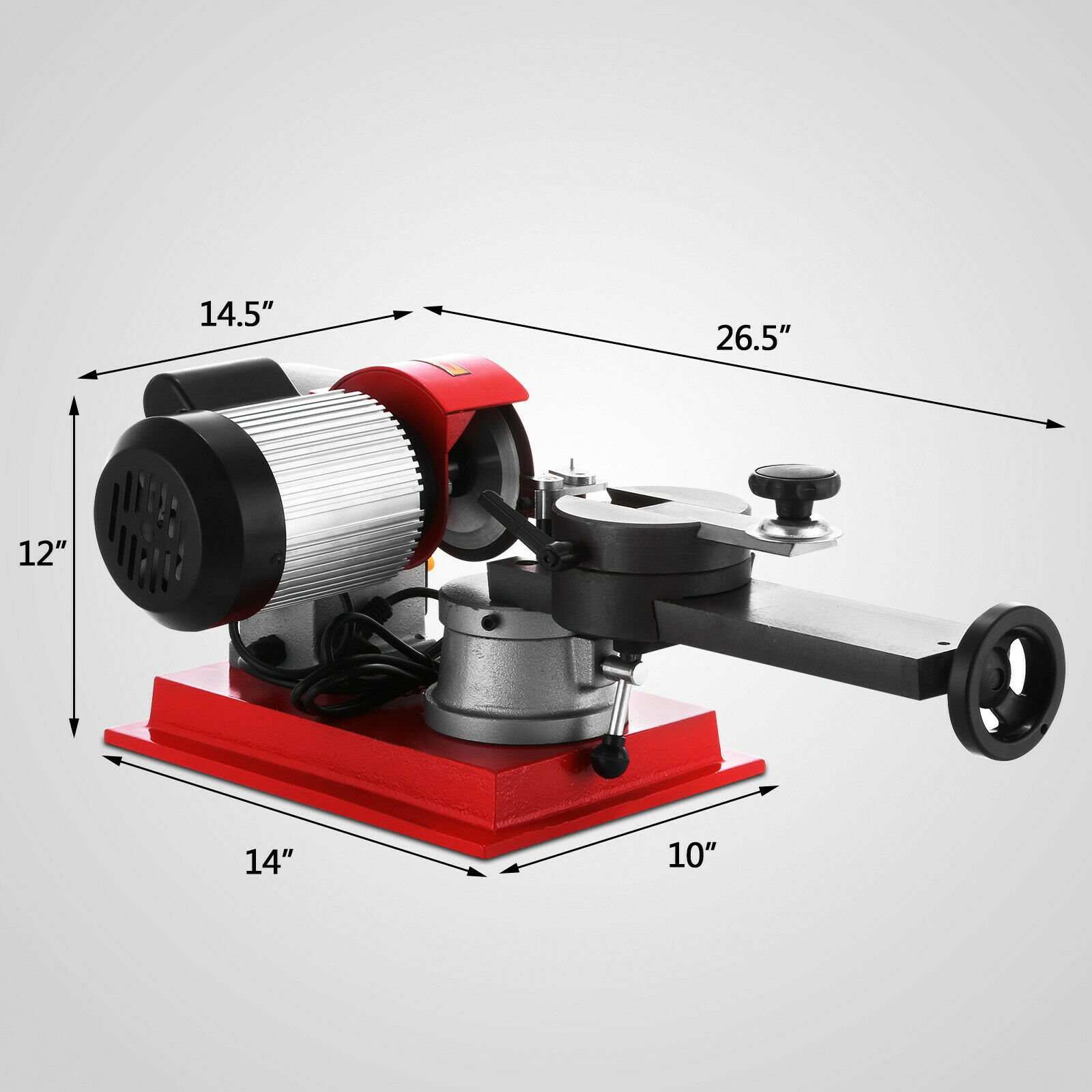

Net Weight: 66.14 lbs / 30 kg

Product Dimension: 30.3"

x

16.93"

x

11.81" / 770

x

430

x

300 mm

Package Dimension: 16.93"

x

16.93"

x

13.58" / 430

x

430

x

345 mm

Package Content:

ORDERS

NAME

DESCRIPTION

QT

1

Main Machine

1 Set

2

Sanding Wheel

φ125*10*32*5*2mm

1Tablet

3

Saw Centering

φ22、φ30、φ25

Each 1 Set

4

Saw Centering

φ40、φ25.4

Each 1 Set

5

Allen Wrench

5mm、

Each 1 Set

6

Cross

4*100

1Set

7

Open-end Wrench

12*14

1Set

8

Manual

1

9

Certificate

1

10

Packing List

1